Dear Rolex-Fans,

after Rolex has published the patent application for the Ringlock-system (EP 1916576A1, „Boîte de montre-bracelet étanche“, published 30.04.08) I would like to explain the sophisticated design of the Ringlock-system.

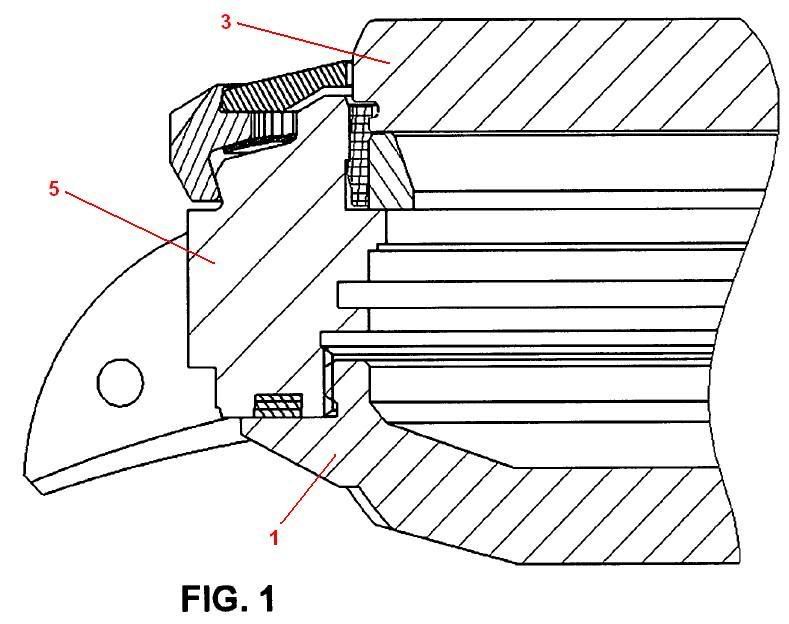

At first please find a picture of the common divers watch design. As an example Rolex has choosen the case of a Sea-Dweller 16600:

(Source: EP1916576A1 with some personal additions)

The forces resulting from the water pressure are directed from the sapphire crystal (3) to the caseback (1) passing the watch case (5), which must be dimensioned accordingly. The measurements of a watch with a testing depth of 1550 resp. an allowed diving depth of 1200 m (Sea-Dweller 16600) can be kept in wearable dimensions, but with depths of 4900 (!) resp. 3900 m the necessary measurements would become extremely and would result in a watch with nearly unwearable dimensions.

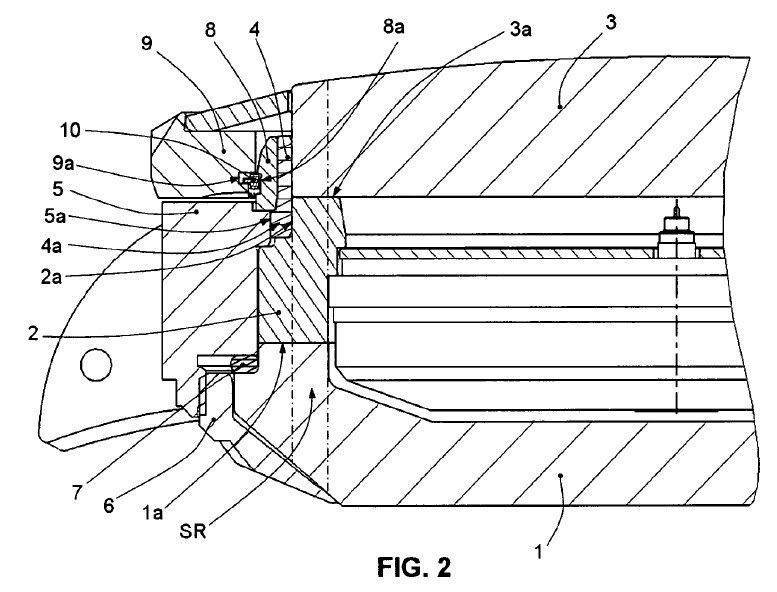

For reducing the measurements of a divers watch able to resist such high pressures it is necessary to optimize the flow of forces between crystal, case and caseback. Rolex has realized an optimization using a tricky design, called Ringlock-system:

(Source: EP1916576A1)

The resulting forces in the Ringlock-system are directed from the sapphire crystal (3) directly to the caseback (1) passing an inner ring (2), but bypassing the case (5). The flow of forces ist therefore directed vertically within the zone „SR“. Due to this design the case (5) „only“ has to bear the waterforce resting on itself and on the bezel, which is due to the smaller area much lower than the force resting on the sapphire crystal. Therefore the case (5) is considerably relieved and can be dimensioned thinner. The caseback (1) itself is held by an outer ring (6), which is screwed into the case (5) and equipped with the common fluting for the Rolex-caseopener. It seems that caseback (1) and outer ring (6) are two separate parts, which are holded against each other only if the outer ring is screwed in the case (5). With the outer ring screwed into the case, the caseback (1) is also pressed against the seal (7) and realizes in conjunction with the seal (4) for the sapphire crystal the complete sealing of the inner compartment.

The Deepsea consists of two statically nearly independent zones:

1. the highly loaded inner zone constisting of crystal (3), inner ring (2) and caseback (1)

2. the lower loaded outer zone consisting of bezel (9), case (5) and outer ring (6)

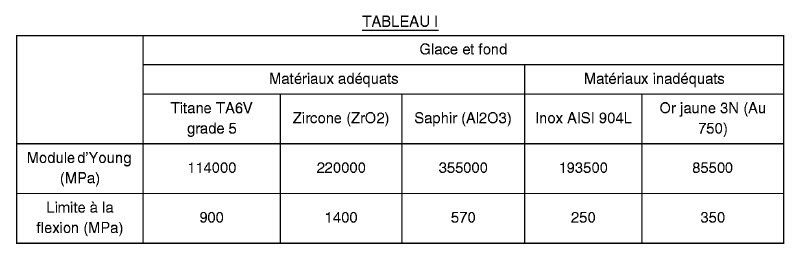

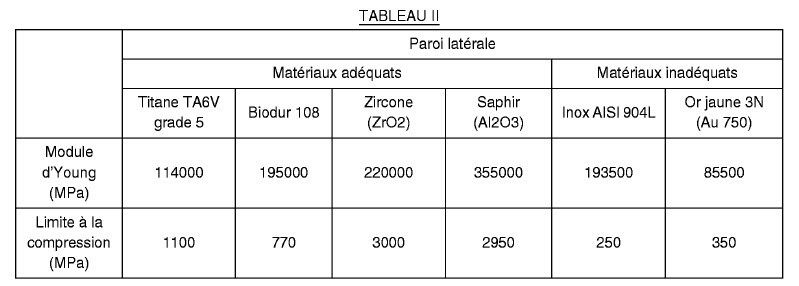

As the relatively small inner ring now has to bear the complete waterforce resting on the sapphire crystal, a highpressure resistant material is necessary. In addition Rolex uses for the first time a caseback made out of Titan for further reducing of weight and height. The following comparison tables show the suitable and non suitable materials for crystal and caseback (Tab. 1) and for the inner ring (Tab. 2):

(Quelle: EP1916576A1)

Rolex has decided to use the following materials:

Caseback: Titan TA6V Grade 5, Titan alloy containing also Vanadium and Aluminium, the allowed bending stress is approx. 4-times higher than for stainless steel AISI 904L (900 to 250 Mpa) in conjunction with approx. 1,75-times less weight..

Inner Ring: Biodur 108, austenitic stainless steel with a high nitrogen content, the allowed compressive stress is approx. 3-times higher than for stainless steel AISI 904L (770 to 250 Mpa).

As you can see not only the design of the Deepsea, but also the choosen materials are very sophisticated.

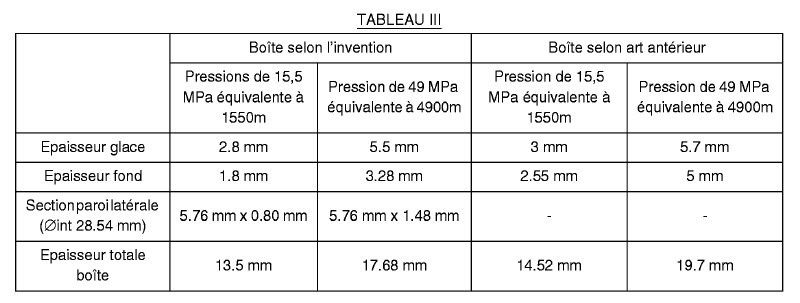

Finally please find the decisive comparison table showing the thickness of the Deepsea (allowed diving depth 3900 m, testing depth 4900 m) and the Sea-Dweller (allowed diving depth 1200 m, testing depth 1550 m) each in conventional design and when using the Ringlock-system:

(Quelle: EP1916576A1)

The rows show from top to bottom the thickness of crystal, caseback, inner ring and the total thickness of the watch. The columns show from left to right:

1. A special Sea-Dweller 16600 with Ringlock-System

2. The Deepsea with Ringlock-System as introduced in Basel

3. The well known Sea-Dweller 16600 in conventional design without Ringlock-system

4. A Deepsea in conventional design without Ringlock-system

A Deepsea in conventional design would result in a total thickness of 19.7 mm (!) and the caseback only would need a height of already 5 mm. The total thickness saving when using the Ringlock-system results at 2.02 mm. Using the Ringlock-system on a Sea-Dweller 16600 would only save 1.02 mm on the total thickness, as the waterpressure is much more lower than for the Deepsea.

Hopefully the information was not too scientific and able to show, that for the realization of the Deepsea a very sophisticated design and choice of material was required. With all this efforts a “profane” divers watch becomes a real hightech product.

Best Regards

Matthias

Ergebnis 1 bis 10 von 10

Hybrid-Darstellung

-

10.06.2008, 11:41 #1

Inside the Deepsea: The Ringlock-System in Detail

The difference between men and boys is the price of their toys.

Ähnliche Themen

-

GMT im Detail

Von uhrenmaho im Forum Rolex - Haupt-ForumAntworten: 23Letzter Beitrag: 10.03.2009, 23:52 -

Submariner en détail

Von Eddm im Forum Rolex - Haupt-ForumAntworten: 77Letzter Beitrag: 14.07.2008, 19:28 -

Outside the Deepsea: The Glidelock-Clasp in Detail

Von Prof. Rolex im Forum English discussion boardAntworten: 5Letzter Beitrag: 18.06.2008, 18:54 -

Das Ringlock-System der Deepsea

Von Prof. Rolex im Forum Rolex - Tech-TalkAntworten: 27Letzter Beitrag: 15.05.2008, 13:43 -

En Détail - Eleganz pur

Von Kermit im Forum Rolex - Haupt-ForumAntworten: 23Letzter Beitrag: 11.05.2007, 14:49

Zitieren

Zitieren

Lesezeichen